◆ Dust particle counter is an instrument used to measure the number and size distribution of dust particles in a unit volume in a clean

environment. It can be widely used in the production enterprises and scientific research departments, such as drug inspection

institutes, blood centers, epidemic prevention stations, disease control centers, quality supervision institutes and other authoritative

institutions, electronic industry, pharmaceutical workshops, semiconductor, optical or precision machining, plastics, paint spraying,

hospitals, environmental protection, inspection institutes and so on.

◆ The basic principle of the air particle counter is that the detection laser of the optical sensor is received by the photosensitive element

after being scattered by the dust particles and generates a pulse signal. The pulse signal is output and amplified, and then the digital

signal processing is carried out. By comparing with the standard particle signal, the comparison results are expressed with different

parameters.

Feature Description:

◆ The dust particle counter is used to measure the number and size distribution of dust particles in a unit volume in a clean

environment, with a maximum sampling concentration of 35000 particles / L.

◆ Semiconductor laser light source, service life of 10 years.

◆ Microcomputer control, touch screen operation, automatic test and display test report.

◆ 6 channels (0.3, 0.5, 1.0, 3.0, 5.0, 10 μ m) of test particle size can be detected simultaneously.

◆ The sampling period can be set by itself, with a minimum of 6S.

◆ The instrument is portable, with battery, and the endurance time is ≥ 5h.

◆ The system can be self-cleaning, with self-cleaning time ≤ 10min.

◆ The instrument has a thermometer interface, and the monitoring report contains temperature and humidity data.

◆ Automatic data storage, built-in micro printer, results can be printed directly.

◆ U disk file data export can be directly opened in Excel.

Model and technical parameters:

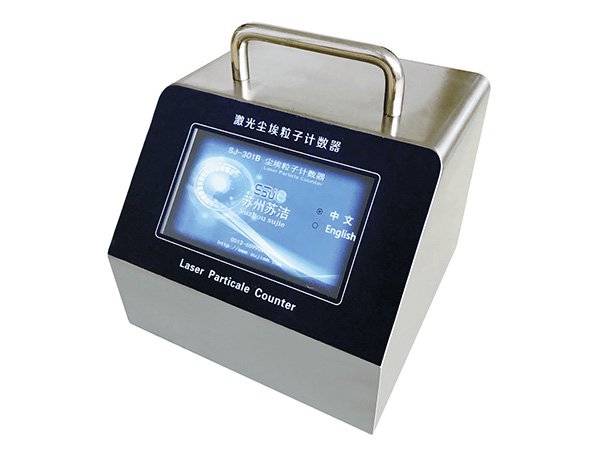

Model | Sj-301b laser dust particle counter |

Sampling flow rate | 2.83L/min ±5% |

Particle size grading | 0.3um,0.5um,1um,3um,5um,10um |

Laser source | Long life laser diode, 10 years service life |

Imported air pump | Stable continuous operation, energy saving and environmental protection |

Verification standard | GB/T6167-2007,JJF1190-2008 |

Repeatability relative error | <±10% |

Particle size distribution error | <±30% |

Maximum sampling concentration | 35000 / liters |

Clean-down capability | ≤10min(count 3 times in 10 minutes to zero, 95% confidence) |

Sampling period | User self setting (5-9999 seconds) |

Sampling delay | User set (1-100s) interval 1-1800s |

Number of UCL samples | 1∽50 |

Number of UCL sampling points (location) | 2∽50 |

Working hours | Continuous test time about 5 hours |

Data memory capacity | 1-5000 sets of measurement data, which can be queried |

Counting mode | Cumulative number |

Screen display | Color 5 Inch Touch Screen |

Printing mode | Built-in Thermal Printer |

Charging power supply | AC 220V / 50Hz |

Built in lithium battery | DC 16.8v 2.2ah |

Charging adapter | Input 100-240V 50Hz, output 16.8v 2A |

Battery charging time | 6 hours |

Cleanliness level judgment standard | Iso14644-1, GMP static, GMP dynamic |

Temperature and humidity | Matching |

Data communication interface | USB |

Environmental Science | Operating environment: 0-40 ℃ relative humidity 10-90% |

Storage environment: - 30 ℃ ~ 45 ℃ relative humidity 0 ~ 90% | |

Standard accessories | Isokinetic sampling head, sampling head connected with PVC hose (inner diameter 6mm), self-cleaning filter, tripod, printing paper, portable protection box, charging adapter, U disk, operation manual, original calibration report, certificate of conformity |

Outline size | L 170 x W 170 x H 160 |

Texture of material | SUS304 stainless steel |

Weight (including battery) | 2.4Kg |